Book Free Site Visit

Bid goodbye to your home painting hassles with our expert supervision

Interior painting plays a crucial role in enhancing the appearance, functionality, and atmosphere of commercial properties. Professional interior painting services can transform your space, making it more inviting and productive for employees and appealing to clients.

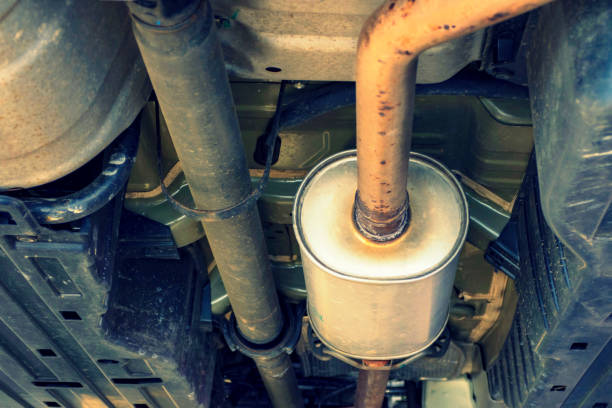

Understanding Corrosion Protection

Corrosion protection is essential for preserving the integrity and longevity of metal structures, especially in industrial and marine environments. At Lzpaint, we use advanced coatings from brands like **Asian Paints Apcolite** and **Berger Red Oxide** to protect against rust and corrosion.

Various Types of Corrosion Protection Coatings

We offer a range of corrosion protection solutions, including zinc-rich primers, epoxy coatings, and polyurethane topcoats. These coatings are specifically designed to protect metal surfaces from environmental and chemical exposure.

How Corrosion Protection Coatings are Applied

The application process includes:1. **Surface Preparation**: Abrasive blasting to clean and profile the surface.2. **Primer Application**: Applying zinc-rich primers for base protection.3. **Topcoat Application**: Applying epoxy or polyurethane topcoats for enhanced durability.4. **Inspection and Testing**: Ensuring coating adherence and thickness for optimal protection.

Materials and Technologies Used in Corrosion Protection

We use high-performance materials from **Asian Paints** and **Berger**. Technologies include airless spraying and electrostatic application for precise and uniform coating coverage, ensuring maximum protection.

Maintaining Corrosion Protection Coatings for Longevity

Regular maintenance, including inspections and reapplication, is critical for maintaining the effectiveness of corrosion protection coatings. Our services ensure ongoing protection and compliance with industry standards.

Factors Influencing the Cost of Corrosion Protection

The cost of corrosion protection is influenced by factors such as:1. **Material Selection**: Using premium coatings like **Asian Paints Apcolite** may have a higher upfront cost but provide superior protection.2. **Surface Area**: Larger metal surfaces require more materials and labor.3. **Environmental Conditions**: Harsh environments may necessitate specialized coatings, impacting costs.

Why Lzpaint is the Best Choice for Corrosion Protection

At Lzpaint, we combine industry expertise with high-quality materials from **Asian Paints** and **Berger** to deliver effective corrosion protection solutions. Our focus on durability, compliance, and customer satisfaction ensures your structures remain protected.

Gallery

Blogs from Corrosion Protection

FAQ'S on Corrosion Protection

Innovative Corrosion Protection Solutions

"LzPaint offers state-of-the-art corrosion protection solutions that extend the life of your assets. Our expertise in advanced coatings ensures superior protection against the harshest environmental conditions."

Safeguarding Your Investments

"Protecting your investments is our priority. LzPaint’s corrosion protection services are designed to preserve the integrity and longevity of your infrastructure, reducing maintenance costs and downtime."

Uncompromised Quality and Durability

"LzPaint is committed to delivering corrosion protection solutions that offer uncompromised quality and durability. Our cutting-edge coatings are engineered to withstand the toughest environments."